INVESTMENT CASTING

Wax Panel Mold

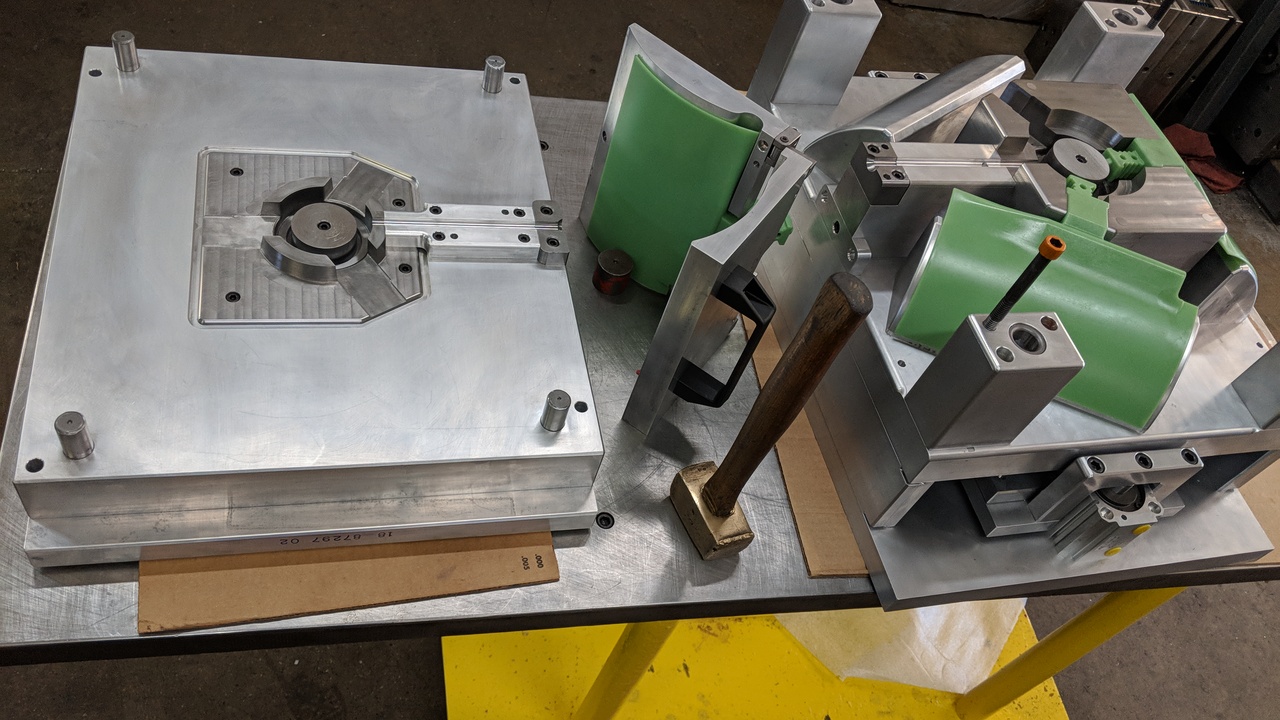

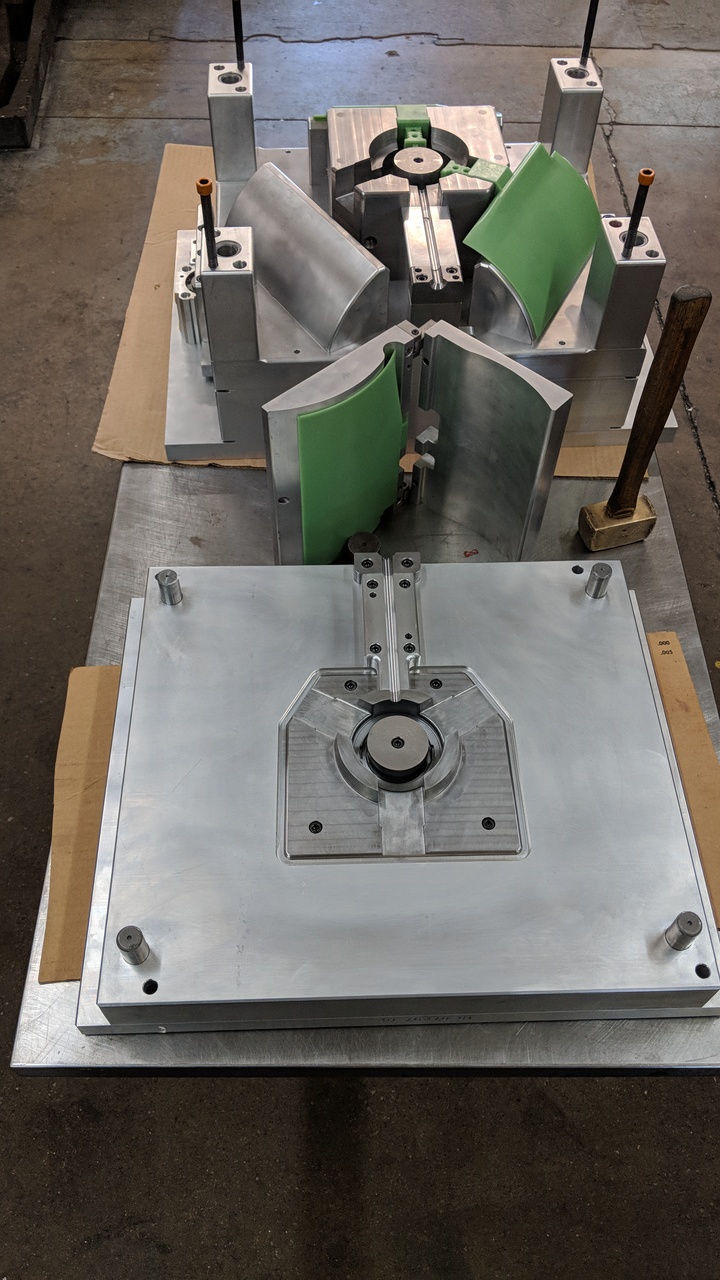

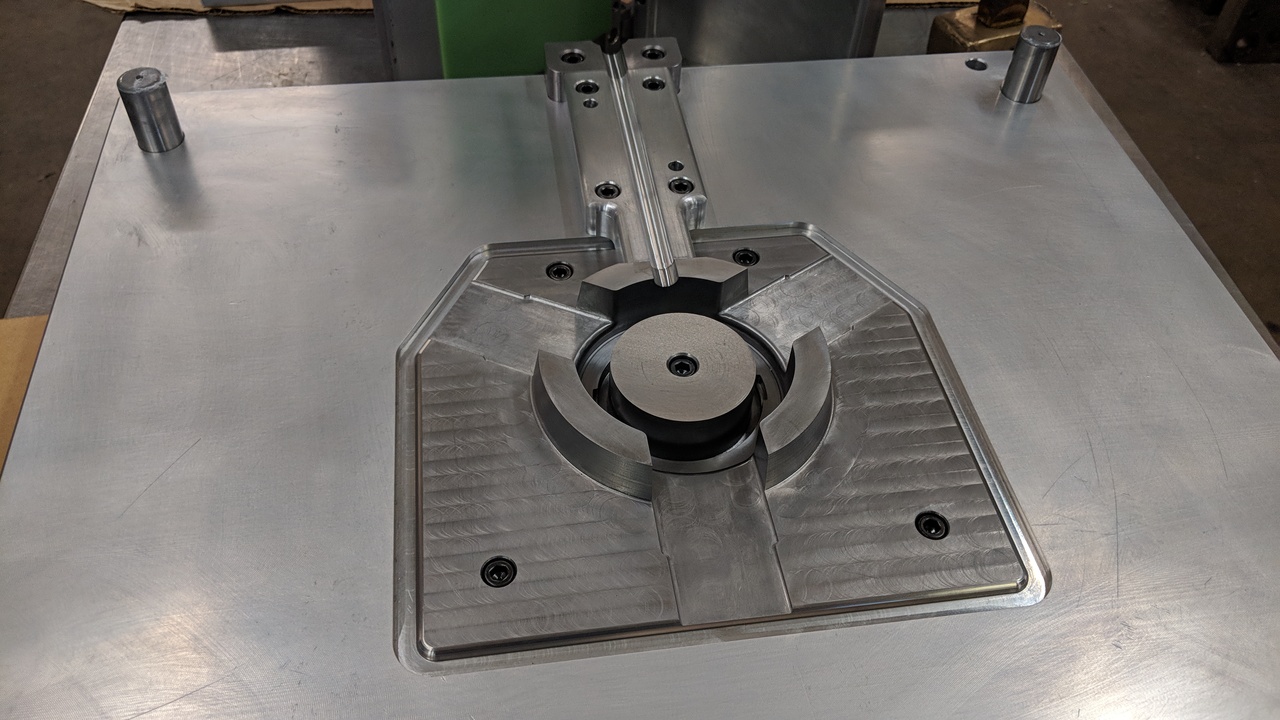

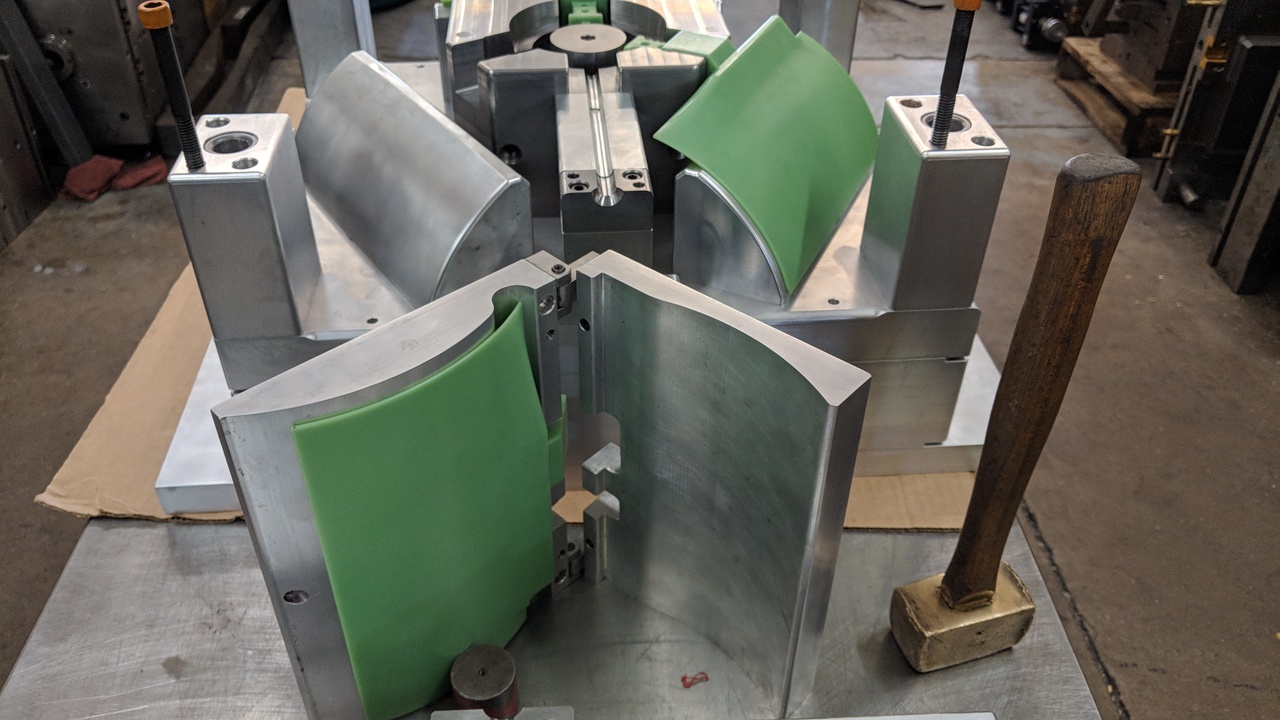

Dognut Die and Setters

Fin Mold and Chill

#8118 Exhaust Manifold Capping Die

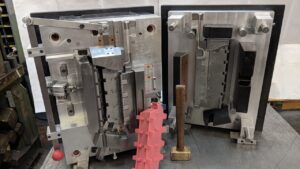

MOLD BUILDING

Built to the highest quality standards, we specialize in building precision plastic molds, including the hot runner and unscrewing types, die cast dies, and related components. Our engineering staff is available for your part and mold design requirements.

INJECTION MOLDING

We can build to your furnished designs, solid models, surface data or wire frames. We operate 2 shifts per day, and have 20 employees with 3,000 man-hours/month working capacity allowing us to run some of our equipment unattended for maximum productivity.

SECONDARY OPERATIONS

We have dedicated manpower and equipment allowing us to give you excellent lead times for your mold repair and revision requirements. We also have our own plastic custom molding manufacturing area enabling us to sample molds and do production runs for our customers.

ASSEMBLY

Our facility has 8,250 square feet of manufacturing and office space. We are familiar with close tolerance work and know the importance of on-time deliveries and quality control checks.

- Plastic Injection Molds

- Die Cast Dies

- Injection Molds

- Wire EDM

- Plastic Parts

- Forging Dies

- Custom Molding

- Die Repair

- Mold Repair

- CMM Fixtures

- Precision Machining

- Injection Molding

- CNC Machining

- Precision Grinding

- Moldmaking

- Electrode Machining

- Prototype Molds

- Mold Design

- Prototype Parts

- EDM machining

AVAILABLE OUTSOURCED RESOURCES

- CERTIFIED ANODIZING AND PASSIVATION *Nadcap approved

- CERITIFED WELDING *Nadcap approved

- CERTIFIED NDT SERVICES *Nadcap approved

- CERTIFIED MICRO LASER WELDING

- CERTIFIED HEAT TREATING *Nadcap approved

- GEAR HOBBING

- THREAD GRINDING

- WATER JETTING

- LASER ENGRAVING

- MATERIAL SOURCING WITH TEST REPORTS AND CERTIFICATIONS

- NICKEL PLATING

- NITRIDE PLATING

- CHROME PLATING

- MOLD FLOW AND FEA ANALYSIS

- MOLD DESIGN SERVICES

- MOLD RELEASE COATINGS

- MOLD POLISHING

- MOLD TEXTURING

These are just a few examples of the many innovative capabilities that Alpha Tool & Mold has to offer. For more information on our equipment, past projects and current capabilities, please contact us.